DTF (Direct-to-Film) prints require precise temperature control between 180°F and 205°F (82°C to 96°C) for optimal results, preserving detail and color. Exceeding this range can cause bonding issues, bubbles, or transfer failure. Key factors like film type, environmental conditions, and substrate surface must be considered. Extreme caution is needed when transferring at higher temperatures to avoid damage. Consistent, controlled environments with precise temperature monitoring, regularly calibrated regulators, and real-time adjustments ensure high-quality DTF Prints.

Discover the ideal temperature settings for achieving perfect film transfers with DTF (Direct-to-Film) prints. This comprehensive guide explores the intricate balance between heat and precision, offering insights into how temperature affects print quality. Learn about the optimal range, factors influencing recommendations, and essential precautions when using higher temperatures. Additionally, we provide tips for consistent results and troubleshooting tips to address common temperature-related issues.

- Understanding DTF Prints and Their Sensitivity to Temperature

- Ideal Temperature Range for Optimal Film Transfer Results

- Factors Affecting Recommended Temperature Settings

- Precautions When Using Higher Temperatures

- Tips for Achieving Consistent Results Across Batches

- Troubleshooting Common Issues Related to Temperature Control

Understanding DTF Prints and Their Sensitivity to Temperature

DTF (Direct-to-Film) prints are a specialized form of film transfer technology that offers high-quality results. These prints are sensitive to temperature, making it crucial to understand their optimal application conditions. When applying DTF prints, maintaining consistent and controlled temperatures is essential to ensure the best possible outcome.

Temperature plays a significant role in the chemical process of DTF printing. Exposure to heat can impact the adhesion and curing of the film emulsion onto the substrate. Too high or too low a temperature can cause issues like poor bonding, blurring, or even degradation of the print quality. Therefore, adhering to recommended guidelines ensures that the fine details and colors of the transferred image are preserved, resulting in vibrant and crisp DTF prints.

Ideal Temperature Range for Optimal Film Transfer Results

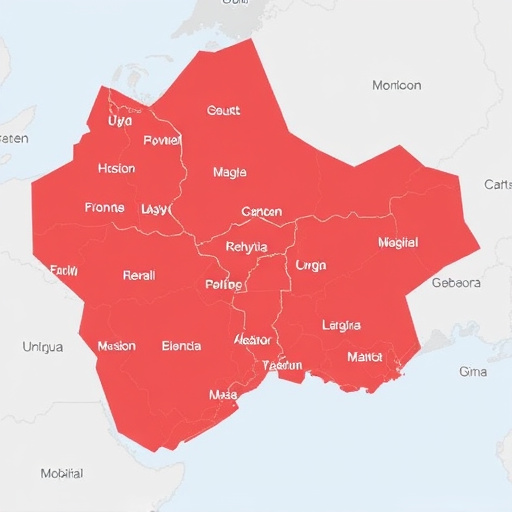

The ideal temperature range for achieving optimal results in film transfers, especially for DTF (Direct to Film) prints, lies between 180°F and 205°F (around 82°C to 96°C). This specific range is crucial as it facilitates the perfect fusion of the film emulsion with the substrate, ensuring a crisp and long-lasting transfer. Temperatures outside this range may result in inadequate bonding, leading to bubbles, shifts in color, or even complete failure of the transfer.

Maintaining the optimal temperature requires careful control and monitoring, often achieved through specialized equipment designed for DTF printing. This meticulous approach ensures that each frame is transferred accurately, preserving the original film’s quality and aesthetic, making it a cornerstone for aficionados and professionals alike in the world of vintage-inspired or archival print creation.

Factors Affecting Recommended Temperature Settings

When setting the optimal temperature for film transfers, several factors come into play. The first consideration is the type of film and its intended use—whether it’s for DTF (Direct to Film) prints or other applications. Different films have varying sensitivities and melting points, so understanding these properties ensures the best results without damaging the material.

Another crucial factor is the environment in which the transfer takes place. Room temperature and humidity levels can significantly impact adhesion and long-term stability. Additionally, the surface onto which the film is applied plays a role; smoother surfaces may require lower temperatures to prevent leaving fingerprints or causing warping.

Precautions When Using Higher Temperatures

When working with higher temperatures for film transfers, it’s crucial to exercise caution. Exceeding recommended levels can cause irreversible damage to the original material and potentially harm your equipment. Always remember that heat is a powerful tool; too much of it can lead to scorching, melting, or discoloration of the film, resulting in poor-quality DTF prints.

Additionally, higher temperatures may accelerate aging processes, making the transfer more susceptible to fading over time. It’s essential to balance the desire for crisp, clear images with the need to preserve the integrity of the original. Always follow best practices, such as using precision temperature controls and monitoring the process closely, to ensure optimal results without compromising the safety of your materials.

Tips for Achieving Consistent Results Across Batches

To achieve consistent results with film transfers, it’s crucial to maintain a controlled environment and adhere to specific temperature guidelines for each batch. The recommended temperature setting for applying film transfers, often referred to as DTF Prints, typically ranges between 130-150°F (54-66°C). This range ensures that the adhesive on the transfer paper activates evenly, allowing for a secure bond with the receiving surface without causing damage.

Consistency is key; using a thermometer during the process can help maintain these precise temperatures. Allow enough time for the heat to set properly, as rushing the process might lead to uneven adhesion or potential bubbling. Remember, small variations in temperature can impact the final result, so monitoring and adjusting accordingly are essential practices for achieving professional-looking film transfers across multiple batches.

Troubleshooting Common Issues Related to Temperature Control

When it comes to film transfers, maintaining the right temperature is key to achieving crisp and accurate results with your DTF Prints. One common issue arises from inconsistent heating, leading to uneven or poor print quality. To avoid this, ensure your equipment has a precise temperature control mechanism in place. Regularly calibrate and test your device to guarantee consistent heat distribution throughout the transfer process.

Another potential problem is overheating, which can cause warping or melting of the film. Setting an optimal temperature range tailored for different types of films and materials will prevent these issues. Monitoring the temperature during printing allows you to make real-time adjustments, ensuring each print receives the exact warmth required for ideal results.